Leading textile solutions provider, SHIMA SEIKI MFG., LTD., based in Wakayama, Japan, will showcase its innovations at the upcoming JIAM 2024 Japan International Apparel & Non-Apparel Manufacturing Trade Show in Osaka, Japan. At JIAM, the company will promote its three main product lines to the international market: Computerized cutting machines (NC cutting machines), Computerized flat knitting machines, and Design software.

The theme of SHIMA SEIKI’s exhibition at JIAM 2024, SHIMA SEIKI Reborn, highlights the company’s renewed commitment to innovation. This concept is embodied in the launch of the brand-new ‘R’ series models, featured in both the computerized cutting machine and computerized knitting machine lineups.

Computerized Cutting Machines (NC Cutting Machines)

P-CAM® R

While SHIMA SEIKI is renowned as a leading manufacturer of flat knitting machines, it also holds the largest market share for computerized cutting machines in Japan. With the introduction of the new P-CAM® R, Japan’s top-selling cutting technology is now available to the global market.

Redesigned as a high-performance flagship model in SHIMA SEIKI’s computerized cutting machine (NC cutting machine) lineup, the P-CAM® R delivers enhanced productivity and precision. Its increased structural stiffness and knife distortion sensor ensure greater cutting accuracy. An independent drilling unit works alongside the cutting head, enabling simultaneous cutting and drilling for improved efficiency.

User-friendly features include simplified maintenance, enhanced operability, and increased operator safety, thanks to a standard entry prevention cover. Cloud connectivity enables real-time monitoring of machine operations, production data analysis, and consumable management, integrating cutting-edge IT capabilities.

The P-CAM® R also addresses sustainability through improved material efficiency, reduced power consumption, and a lower environmental footprint. The machine will be showcased alongside the PSPR® 2L fabric spreading machine, which includes a layup function to “relax” fabric for precise cutting. Live demonstrations of cut-and-sew garment fabric cutting will take place throughout the day.

P-CAM®160 Pattern Matching Premium

The P-CAM®160 Pattern Matching Premium, a single-ply computerized cutting machine (NC cutting machine), is designed for precise pattern-matched cutting of plaids, stripes, and borders. Equipped with a line-scan camera, it reads the entire fabric pattern as it is fed into the machine, aligning it with marking data created using SDS®-ONE APEX4 CAD software. This ensures pattern-matched cutting while compensating for fabric skew and distortion.

A key feature is its ability to scan the next fabric pattern in the scanning area while cutting is performed in the cutting area, significantly improving production efficiency. Enhanced fabric suction eliminates the need for a sheet sealer, reducing material costs and promoting sustainable manufacturing. Live demonstrations of the Pattern Matching Premium will showcase the cutting of checkered fabric for jackets.

P-CAM®120C

The P-CAM®120C is a versatile computerized cutting machine (NC cutting machine) designed for cutting sheets of carbon- and glass-fiber reinforced plastic (CFRP and GFRP) pre-impregnated composites (prepregs). It supports multiple cutting methods, including drag knife, reciprocating knife, and ultrasonic knife, making it suitable for a wide range of materials such as rubber, leather, vinyl, thermoplastics, adhesive materials, and water-repellent fabrics. The machine can handle single-ply materials up to 20mm thick or multi-ply applications.

With compact dimensions starting at a cutting width of 1,180mm and a length of 880mm (extendable to meet customer requirements), the P-CAM®120C is equipped with features like dust prevention, auto knife cleaning, and cutting mat laydown to address the specific needs of cutting high-performance materials. It is ideal for applications in the automotive, aerospace, and industrial sectors.

At JIAM, the P-CAM®120C will demonstrate its capabilities by cutting a variety of fabrics on demand.

Computerized Flat Knitting Machines

SWG-XR®

SHIMA SEIKI will showcase its latest-generation flagship WHOLEGARMENT® knitting machine, the SWG-XR®, at JIAM 2024. This advanced machine knits entire garments seamlessly, eliminating the need for sewing or linking. As one of the most sustainable textile production methods, WHOLEGARMENT® knitting uses minimal material to produce single items.

The SWG-XR® is equipped with four needle beds for high-quality WHOLEGARMENT® production, utilizing the proprietary SlideNeedle™. It also features a redesigned sinker system and a compact, lightweight carriage with four systems, along with automated yarn carriers, enabling over 25% greater productivity compared to previous models. It supports a broader range of yarns for diverse, all-season knits and produces superior-quality fabrics and silhouettes. This includes punchlace patterns, variable stitch knitting, and intarsia knitting. At JIAM, the SWG-XR® will be displayed in a 22LL gauge, ideal for creating 18-gauge fabrics, setting new standards for waste-free, sustainable production.

SWG®041N2

The compact SWG®041N2 WHOLEGARMENT® knitting machine produces various items in their entirety without linking or sewing. As part of the SWG®-N2 “Mini” series, it is ideal for creating small items like gloves, socks, hats, scarves, and accessories, including dog wear, cozies, shoe uppers, bags, glasses cases, and smartphone covers. At JIAM, the SWG®041N2 will demonstrate knitting a 3D business card case in one complete piece.

SVR®093SP

The SVR®093SP is a conventional shaped knitting machine equipped with a loop presser bed for creating hybrid fabrics that combine knit and weave characteristics. Its i-Plating® inverse-plating capability allows intricate patterns like jacquard-style designs in lightweight plain jersey stitch. SHIMA SEIKI innovations such as the Rapid Response R2CARRIAGE®, DSCS® Digital Stitch Control System, and stitch presser enhance its capabilities. At JIAM, the SVR®093SP will produce a helmet shell.

Design Software

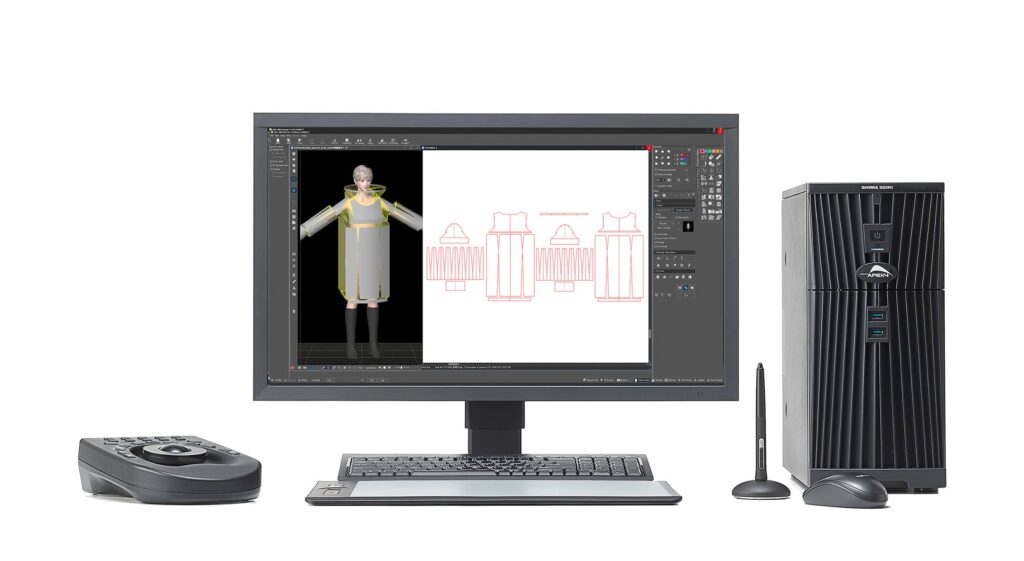

SDS®-ONE APEX4

The SDS®-ONE APEX4 3D design system enhances SHIMA SEIKI’s machine capabilities. Central to the company’s “Total Fashion System,” it integrates production seamlessly, from design to sales promotion. Its ultra-realistic virtual sampling minimizes the need for physical prototypes, saving time, cost, and resources while promoting sustainable production across flat knitting, weaving, pile weaving, circular knitting, and embroidery.

APEXFiz®

The functionalities of SDS®-ONE APEX4 are available as individual software subscriptions through APEXFiz®. This tool supports fashion design, planning, and colorway evaluation, offering realistic fabric simulations and virtual sampling to reduce waste. Designers can bridge the gap between studios and factory floors with machine-ready data for smooth production workflows, further enabling digital transformation in the fashion supply chain.

SHIMA SEIKI Online Services

APEXFiz® Design integrates with web platforms like SHIMA Datamall™, a digital content service for streamlined production, and yarnbank®, a digital yarn sourcing service featuring data from global yarn manufacturers for virtual sampling. Registration for these services is free.

Exhibit Details

- Event: JIAM 2024 (Japan International Apparel & Non-Apparel Manufacturing Trade Show)

- Date: Wednesday, 27th – Saturday, 30th November 2024

- Time: 10:00 AM – 5:00 PM

- Location: INTEX OSAKA, 1-5-102 Nanko-kita, Suminoe-ku, Osaka 559-0034 JAPAN

Tel: +81 (0)6-6612-8800 - Organizer: JASMA (Japan Sewing Machine Manufacturers Association)

- Booth: Hall 5, Stand 5-B001

Exhibited Technology

- P-CAM® R, P-CAM®160, P-CAM®120C: Computerized cutting machines

- P-SPR®2L: Fabric spreading machine

- SWG-XR®124 22LL: WHOLEGARMENT® knitting machine

- SWG®041N2 15G: WHOLEGARMENT® knitting machine

- SVR®093-SV 14G: Computerized flat knitting machine

- SDS®-ONE APEX4: 3D design system

- APEXFiz®: Design subscription software

- SHIMA Datamall™: Digital content web service

- yarnbank®: Digital yarn sourcing web service